Leading the Way in Evaluation at Screening Laboratories

Accuracy Materials Testing: Unwinding the Features

Are you interested concerning the interesting world of precision materials screening? Look no more! In this short article, we will certainly unravel the buildings of products via accurate screening methods (testing laboratories). You will learn more about the importance of products screening, vital strategies utilized, as well as exactly how to gauge material homes properly. We will likewise discover the common difficulties dealt with in precision materials testing and the current breakthroughs in innovation. Prepare to dive into the realm of precision materials screening and also increase your knowledge!

The Value of Precision Products Screening

You could be asking yourself why precision products testing is so essential. Well, allow me inform you, it plays a critical function in various sectors. Precision products evaluating guarantees that the products utilized in manufacturing meet the required requirements. By testing the buildings of materials, such as strength, firmness, and also resilience, manufacturers can determine if they are suitable for their intended applications. This aids in preventing pricey failings as well as crashes down the line.

Second of all, precision products testing is vital in research and also growth. Researchers and also designers require accurate data on the residential or commercial properties of materials to create ingenious items and enhance existing ones. Whether it's creating a new alloy for aerospace applications or enhancing the efficiency of electronic tools, exact testing supplies the needed information to make informed choices.

Secret Methods for Materials Screening

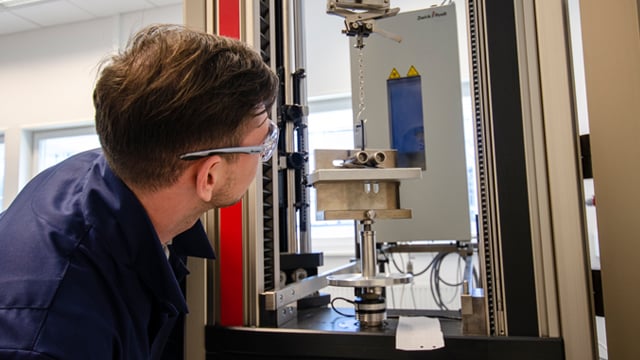

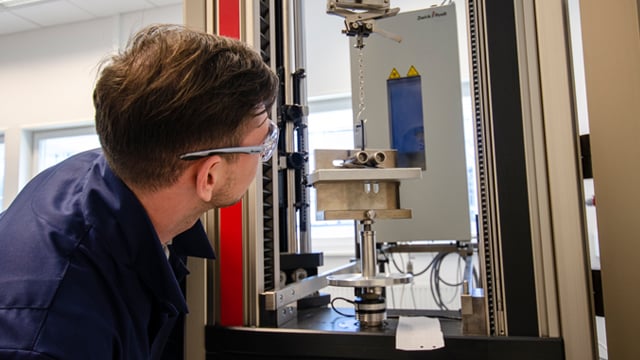

To efficiently evaluate the attributes of different products, it's vital to comprehend the crucial techniques used in their testing. One of the most usual methods is tensile screening, where a sample of the product is subjected to tension till it breaks. This aids determine properties such as best tensile strength and also elongation. One more method is hardness testing, which determines a product's resistance to imprint or scraping. It is usually made use of to assess the toughness and also longevity of products. Additionally, impact testing is made use of to assess a material's capacity to hold up against sudden forces or shocks. This includes striking a sample with a pendulum and also gauging the energy soaked up. An additional important technique is microscopy, which enables for the evaluation of a material's microstructure. This can help recognize any problems or abnormalities that might impact its efficiency. Lastly, thermal evaluation methods, such as differential scanning calorimetry as well as thermogravimetric analysis, are used to research a material's thermal habits and security. Comprehending these key methods is essential in precisely click over here examining the properties and also efficiency of various materials.

Comprehending Product Residences and also Their Measurement

By recognizing these dimension strategies, you can make enlightened decisions concerning which products are best matched for your certain needs. One frequently determined residential property is the tensile toughness of a product, which refers to its capability to hold up against drawing forces without damaging. The most extensively utilized technique for gauging solidity is the Rockwell firmness test, where a ruby or steel sphere is pushed into the material and also the depth of imprint is gauged.

Common Obstacles in Accuracy Materials Screening

One obstacle in precision materials screening is making sure precise as well as regular dimensions throughout the testing procedure. When conducting accuracy materials testing, you have to be alert in preserving the honesty of your measurements. This means taking steps to reduce any type of sources of error that might compromise the accuracy of your outcomes.

One usual challenge in precision materials testing is the correct calibration of testing devices. This can be done by utilizing certified recommendation materials or by complying with well-known calibration treatments.

Preserving a visit here regulated screening environment is vital for exact and consistent dimensions. Elements such as temperature, humidity, and also resonance can all influence the habits of products and, subsequently, the outcomes of your tests. It is vital to meticulously manage these ecological variables to guarantee dependable and also reproducible measurements.

Developments in Materials Testing Innovation

Advances in materials checking innovation have actually reinvented the way measurements are taken, guaranteeing more exact as well as regular outcomes. You can now benefit from cutting-edge devices as well as strategies that have significantly boosted the accuracy as well as dependability of products screening.

Among the significant developments is the development of non-destructive screening methods. These strategies permit you to analyze the residential or commercial properties and also attributes of materials without triggering any damage. Ultrasonic testing, for instance, uses high-frequency acoustic waves to detect problems or abnormalities in a material. This non-invasive approach not only conserves pop over to this web-site time as well as sources however likewise allows you to review the stability of a material without compromising its architectural stability.

One more advancement is using sophisticated sensors as well as instruments. These gadgets can capturing information with higher resolution and also level of sensitivity, giving you with more thorough and also precise measurements. Whether it's stress determines, accelerometers, or thermal imaging cameras, these cutting-edge devices enable you to capture exact details concerning the habits and performance of materials under different problems.

Moreover, the integration of automation as well as fabricated intelligence has structured the materials testing procedure. Automated systems can now perform repetitive jobs with greater rate as well as precision, reducing the danger of human mistake. Additionally, AI formulas can evaluate big quantities of data as well as determine patterns or abnormalities that might not be conveniently noticeable to the human eye.

Final thought

To conclude, precision materials screening is crucial for comprehending the properties of different products. By employing key methods such as mechanical screening, spectroscopy, as well as microscopy, scientists are able to properly measure as well as evaluate material homes. Nevertheless, accuracy materials screening also features its difficulties, such as making sure accuracy and repeatability. Luckily, advancements in technology have helped overcome these challenges, making products checking a lot more efficient as well as reputable. In order to continue pushing scientific borders and also developing ingenious materials, accuracy materials screening will certainly remain a crucial area of research - testing laboratories.